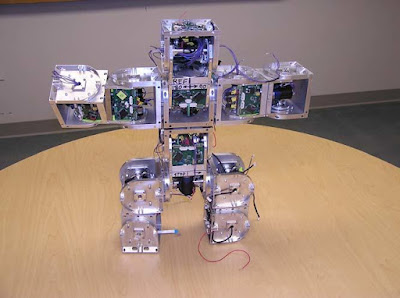

Self-Reconfiguring modular robots or self-moderating modular robots are fully autonomous modular machines having variable geometry. They can be assembled in a semi-automatic manner and vary in shape according to the requirements of the users. The parts of a self-reconfiguring robot are made from polystyrene resin, rubber, and thermoplastic elastomeric resins, which can be easily pieced together if needed to form a complete robot.

In the present day's manufacturing system, most of the parts of most of the industrial units are produced by the use of automated machines that are called self-reconfiguring modular robots. These modular robots have great potential to increase the productivity level of factory employees. This is possible due to the fact that they can work according to the definite instructions given by the engineers and programmers who are operating them. By using some sophisticated programs that are designed especially for self-reconfiguring modular robotic systems, these machines can work according to the changing production line policies and can execute their tasks perfectly without any help.

A self-reconfiguring modular robot is highly useful in several industries that require smooth locomotion in various types of circumstances. These include applications such as mining, construction, and manufacturing, as well as supply chain operations that involve both forward and backward movement. Basically, it is capable of performing both tasks with ease. This is what makes it a great choice for applications that require smooth locomotion in both forward and backward directions. This flexibility is one of the main factors why modular robots have an edge over their counterparts. Since the robots can easily change their shapes, the production process can be fastened to the exact specifications needed by the factory. This allows robots to do tasks that may be tiresome for humans, such as drilling holes and making carts. It also allows factories to have greater control over the robots' movement. The presence of a single unit makes it easy for workers to move the robots from one place to another.

No comments:

Post a Comment